- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 7 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 7 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 9 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 11 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

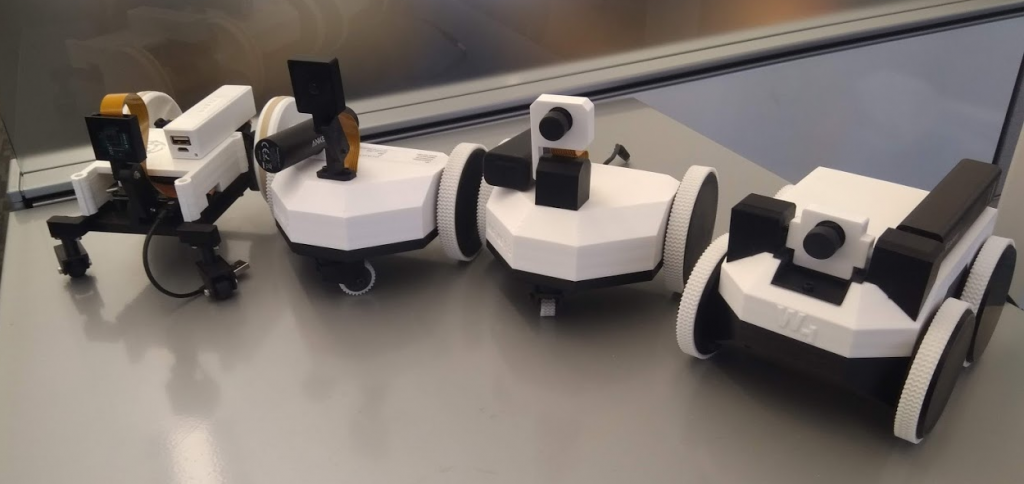

Watney: Fully Open Source 3D Printed Rover

While many vehicle projects implement 3D printing, most of them use them in small parts and portions. So, it’s fascinating to see a device which is 3D printable from start to finish. Nik Ivanov set out to achieve precisely this with Watney, his fully 3D printed rover. Watney is a mobile all-wheel platform comprising entirely open-source parts. It is also unmanned and remotely operated via webcam.

“Watney is a low-cost Raspberry Pi-enabled rover made of readily available parts. The majority of Watney’s parts are 3D-printable. It has a Python and a REST APIs. Watney is all-wheel drive, with each side powered by a geared motor. Because of that, it turns like a tank by spinning each side in opposite directions. It drives best on smooth surfaces, like hardwood, linoleum and tile. For carpeted surfaces, Watney can do “soft turns”, by spinning one side forward and the other alternating backwards and forwards.

The software part of Watney makes it a webcam on wheels. The camera feed is low-latency HD and rover control is accessible via a browser.”

All four of the wheels are driven by a pair of geared motors, so it drives and turns like a tank. The frame and the rest of the mechanical parts can all be 3D-printed on just about any model of printer, making it accessible to any maker with access to a 3D printer. And, all of the electronics are very affordable.

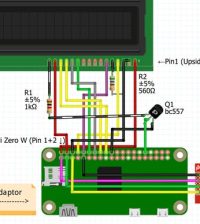

A Raspberry Pi Zero W is the brain of the operation, but the beauty of an open platform like this is that you could easily swap out the controls for something else to meet your needs. In addition to the Pi, there’s a L298N H-bridge motor controller to interface with the dual geared motors, as well as a servo to provide tilt for the SainSmart camera module.