- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 3 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 3 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 5 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 7 months ago

- Building a 3D Digital Clock with ArduinoPosted 12 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

Texas introuduces first inductance-to-digital High Resolution Sensor

In 1820, Johann Schweigger invented the galvanometer – the first tool used to detect and measure electrical currents – considered by many as the first sensor in the world.

This year Texas Intruments proposes a revolutionary technology that can equally be used to implement any type of sensor, from those of movement, rotation and displacement, up to the flow sensors, pressure and force that find application in industrial, automotive, consumer, medical, mobile and many more.

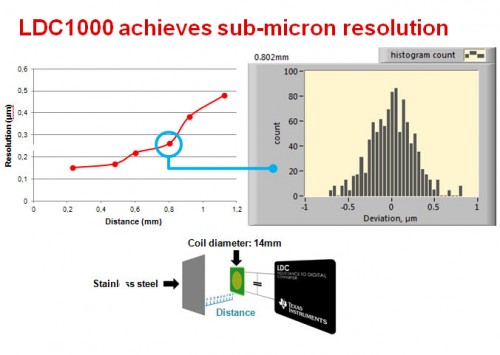

The new technology is based on a low cost device called LDC inductance-to-digital converter, which uses a coil, also in the form of a spring, which creates an electromagnetic field within which is located a conductive target whose motion can be detected with great precision. Even the compression, tension or torsion spring may be perceived and recognized.

Texas Instruments (TI) has unveiled the industry’s first inductance-to-digital converter (LDC), a new data converter category that uses coils and springs as inductive sensors to deliver higher resolution, increased reliability, and greater flexibility than existing sensing solutions at a lower system cost. Inductive sensing is a contactless sensing technology that can be used to measure the position, motion, or composition of a metal or conductive target, as well as detect the compression, extension or twist of a spring, says the company.

Applications for inductive sensing range from simple push buttons, knobs, and on/off switches to high-resolution heart rate monitors, turbine flow meters, and high-speed motor/gear controllers. Given their versatility, LDCs can be used in many different markets, including automotive, white goods, consumer electronics, mobile devices, computing, industrial, and medical.

“LDC technology enables engineers to create sensors using low-cost and readily available PCB traces or metal springs. LDCs provide high-resolution sensing of any metal or conductor – including the human body,” said Dave Heacock, senior vice president of TI Silicon Valley Analog. “LDCs provide system designers with a new platform for developing breakthrough solutions to difficult system problems. We can’t wait to see what they come up with.”