- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 4 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 4 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 7 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 8 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

Novel Material ‘Celleron’ Could Revolutionize 3D Bioprinting for Regenerative Medicine

One of the most exciting frontiers is that of 3D bioprinting, which is highly anticipated and could reveal potentially game-changing biomedical technology. One of the biggest issues prohibiting 3D bioprinting technology is how to make true 3D representative biological structures? But this technology could be about to take an open-source turn, which could accelerate and advance bioprinting as a feasible regenerative alternative to traditional treatments.

Engineers at Swansea University in Wales, have developed a revolutionary biodegradable tissue scaffold. This new biomaterial, called Celleron, comes as both a liquid biopolymer and a filament derivative. The development is led by Dr. Dan Thomas of Swansea University’s College of Engineering, able to 3D print Celleron and replicate the complex underlying structures of complex tissue architectures.

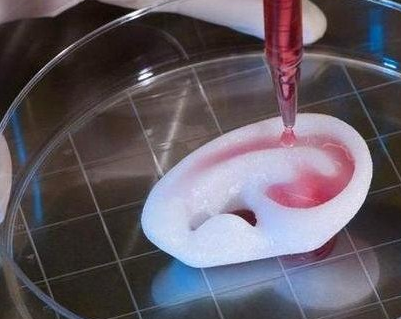

Post 3D printing, Celleron ferments when a biological activator is added, which causes it to become microporous in nature. This ensures that there is a massive increase in surface area and mechanical strength, and that there is a path deep into the structure for the migration of cells. Protein growth factors are then saturated into the porous scaffold to turn it into a biologically attractive composite.

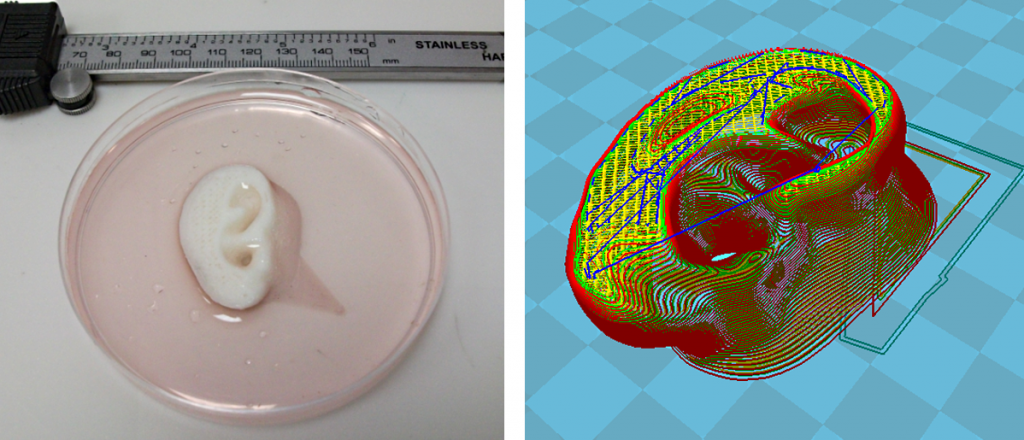

This top-down 3D printing process allows for the fabrication of an accurate structure, so there could uses in a number of applications. Earlier this year the Swansea team bioprinted the complex geometry of a child’s ear from Celleron.

The Swansea team firstly engineered the 3Dynamic Alpha 3D bioprinter. These workhorse 3D bioprinters are currently used by many researchers from across the world to deposit a range of biologically supportive materials.

Next year the Swansea team plan to share this technology for biopolymer formulation and 3D bioprinting processes with researchers from across the world. This is in order to ensure that there is rapid acceleration of this technology so that the area of 3D bioprinting technology can be refined quickly. If successful then hopefully this technology will one day make a significant difference in the lives of many people.

Source: Novel Material ‘Celleron’ Could Revolutionize 3D Bioprinting for Regenerative Medicine