- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 7 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 7 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 9 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 11 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

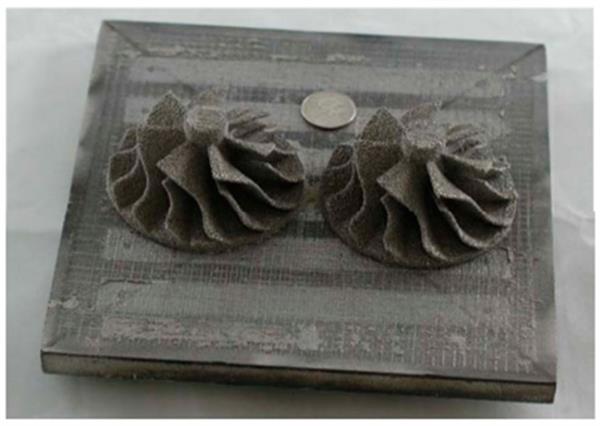

New ORNL study: A full overview of metal 3D printing technologies and their bright future

Metal 3D printing is currently being used for the development of some of the most exciting 3D printed parts around, from airplane engine components to space-bound satellites. But the reality is that metal 3D printing encompasses a very diverse group of technologies that are piled together, even though they use different techniques for forging different sources of metal (powders, wires or even sheets) together. Each, in turn, is suitable for different applications.

Summarizing metal 3D printing as a whole is therefore almost impossible, but a team of researchers from the Oak Ridge National Laboratory (ORNL) in Tennessee have done so anyway. In a remarkable and comprehensive study titled ‘The metallurgy and processing science of metal additive manufacturing’, five ORNL researchers provide a comprehensive overview of everything you could possibly want to know about metal 3D printing.

Various new 3D printing methods are on the horizon: chemical vapor deposition (CVD, currently used for coating), physical vapors deposition (PVD, which uses a vacuum), liquid metal material jetting and friction stir 3D printing. These relatively novel techniques have the ability to change the landscape of metal 3D printing in the near future. The same can be said for Cold Spray technologies, which deposit particles in a high-speed gas stream.

A lot of work still needs to done. Most importantly, the technology’s ability to facilitate geometric complexity needs to be expanded to make 3D printing an indispensable technology. “By enabling new geometries that reduce the number of components in a part or mesh structures that promote body acceptance of implants (for medical implants), metal AM has the potential to make economic sense by displacing parts with inferior performance,” ORNL writes. This also means reducing failure rates and improving machine reliability.

For more information on the current state of metal 3D printing, check out the full article here.

Source: New ORNL study: A full overview of metal 3D printing technologies and their bright future