- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 7 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 7 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 9 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 10 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

Build Your Own SLA/DLP 3D Printer with 3D Printed Parts

A maker named Aldric Négrier has designed and built several 3D printers, many of which he has shared on Instructables.

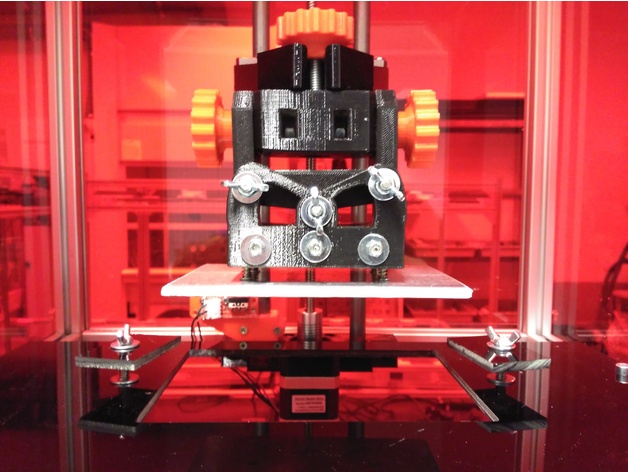

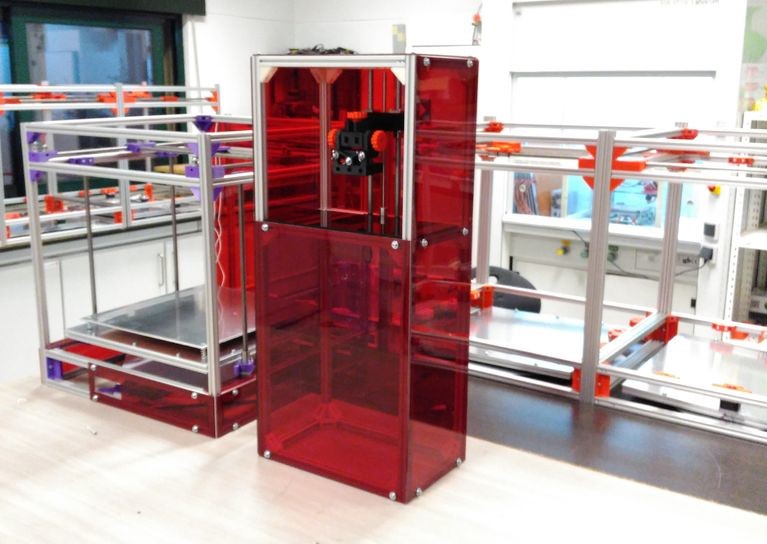

Their latest is the RooBee One, an aluminum-frame SLA-DLP printer named for its bright red color. The design is based on two other open source machines: the Cristelia LCD SLA 3D printer and the Vulcanus MAX, and you can build it yourself with some 3D printed parts and inexpensive hardware.

The files for the 3D printed parts (12 total) are available on Thingiverse, and the Instructable lists the off-the-shelf hardware needed to complete the build. The frame of the printer is built from 20 x 20 mm aluminum profiles connected by M5 screws and nuts, with 32 3D printed corners to steady it. The resin vat can be constructed from plexiglas, with a print bed built from a 5mm aluminum sheet.

Detailed instructions take you step by step through the construction of the Z axis, an adjustable pan and tilt system, projector fixation components, and other structural elements, many of them 3D printed. The printer’s electronics include an Arduino Mega, a RAMPS 1.4 shield, a micro stepping driver, a NEMA 17 stepper motor, an endstop and a 12V transformer. A diagram illustrates how to wire them together and attach them to the printer. Négrier uses an Acer DLP projector, which provides an adjustable build area ranging from 80 x 60 x 200 mm to 150 x 105 x 200 mm.

Source: 3DPrint.com