- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 4 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 4 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 7 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 8 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

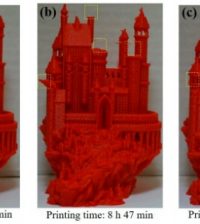

Autodesk’s Project Escher connects multiple 3D printers for faster, scalable large-format 3D printing

Through their Project Escher, Autodesk is now working to turn 3D printing software upside down with a smart 3D printing production line that creates very large objects by running multiple toolpaths between multiple collaborating machines very efficiently. Could this be the future of large scale 3D printing?

Autodesk is no stranger to 3D printing hardware themselves. Their excellent open source Ember 3D printer already showed their dedication to pushing the 3D printing revolution further. But Project Escher is operating on a completely different level. As its name suggests, you don’t even know where to look with the project’s 3D printer, which is essentially several machines working in unison. But the funny thing is, the hardware is inconsequential. As the project’s hardware lead Cory Bloome revealed, “Just to be clear, Autodesk is not releasing a new 3D printer. Project Escher is software and control technology that can work with a new generation of 3D printing hardware,” he said.

Source: Autodesk’s Project Escher connects multiple 3D printers for faster, scalable large-format 3D printing