- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 3 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 3 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 5 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 7 months ago

- Building a 3D Digital Clock with ArduinoPosted 12 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

The future of medical 3D printing: Devices with custom geometries and functionalities

One of the rightly touted breakthroughs of 3D printing in the medical space is the technology’s capability of producing custom orthopedic devices that precisely match specific patient anatomies. University of Minnesota mechanical engineering professor Michael McAlpine wants to take that a step further by integrating customized functionality into the 3D-printed device.

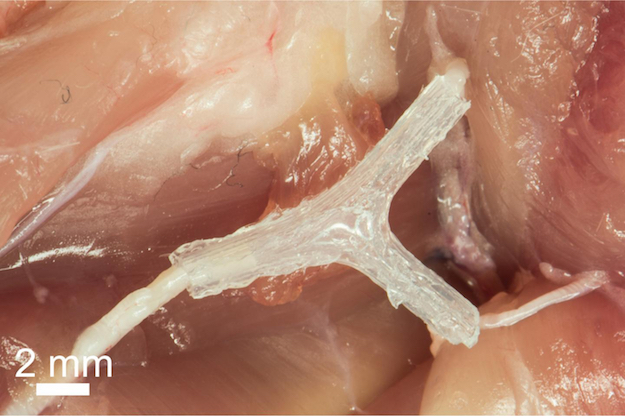

“The big value in 3D printing is customization not just of the geometry but also the functionality,” McAlpine told. “That means building in function from various materials that also may be specific to what the patient needs.” He and fellow researchers have taken a big step in that direction with a 3D-printed silicone guide embedded with proteins to enable nerve regeneration. The technique has been shown to be successful in regenerating the sciatic nerve in rats.

Nerve regeneration in and of itself is a complex process, and that is compounded by the y-shaped geometry of the sciatic nerve, which branches out as it travels down the leg. “A damaged sciatic nerve is difficult, if not impossible, to repair,” says McAlpine. Through the use of a 3D scanner and custom designed 3D printer that allows integration of multiple materials, including plastics, cells and functional materials such as electronic and semiconducting nanoparticles and hydrogels, on the same platform, McAlpine’s team was able to print custom nerve guides that promote both motor and sensory nerve regeneration.

Source: PlasticsToday