- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 2 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 2 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 5 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 6 months ago

- Building a 3D Digital Clock with ArduinoPosted 11 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 12 months ago

- Snowflake with ArduinoPosted 12 months ago

- Holographic Christmas TreePosted 12 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

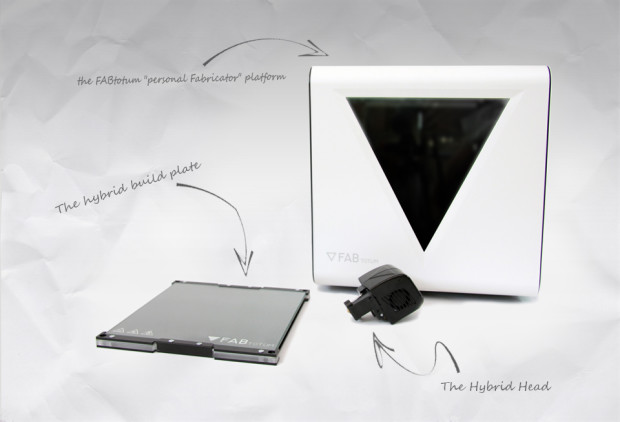

FABtotum PRISM: World’s first All-in-One Low Cost Stereolithography 3D printing platform. 3D print, Mill, Scan

The army knife solution for Digital Fabrication, now on Indiegogo! Starting at $1,300!

With FABtotum PRISM you get the most flexible and advanced multipurpose manufacturing device ever conceived, capable of 3D Printing in SLA with light-curing resins or with FFF on Materials like PLA, PETG, ABS as well as NYLON, HIPS, PC, 3D Milling Foams,Brass,Wood,Aluminum and acquire 3D point clouds and models via multiple 3D scanning methods with the built-in hi-res camera, touch probe and laser.

Design and create small or big components with a huge variety of materials, acquire 3D shapes, modify existing designs and print them in multiple materials and with different technologies as you see fit.

FABtotum PRISM brings design and personal fabrication to a whole new level.

While there can be “better” manufacturing technologies. There is no “better” manufacturing technique.With the addition of the PRISM Stereolithography manufacturing technology you are now able to reach unprecedented levels of details and complexity on top of the capabilities of the FABtotum Personal Fabricator.

FFF/FDM does not produce fine details and can only work with a limited amount of polymers. Engraving is precise and works with lots of materials but require some fiddling with CAM and CAD. DLP and SLS are precise but can be expensive for big volumes and are limited to certain Light-activated resins.

FABtotum PRISM adresses that.The FABtotum is capable of printing autonomously (without being connected to a computer), from cabled LAN, Wireless LAN and even remotely from the Internet (Your Network must be properly configured for this), thanks to the FAB UI, the FABtotum User Interface. Also, users and developers have access to a well known development ecosystem, the Raspberry Pi’s Raspbian Linux distribution to develop more applications. The FABtotum feature a customized web management app, SSH and VNC server on the local network, so with one authorization code you can access all the functions of the machine: 3D Printing, 3D scanning, Milling, Costumizations and Maintenance.

Source: FABtotum PRISM | Indiegogo