- How to Adjust X and Y Axis Scale in Arduino Serial Plotter (No Extra Software Needed)Posted 4 months ago

- Elettronici Entusiasti: Inspiring Makers at Maker Faire Rome 2024Posted 4 months ago

- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 6 months ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 8 months ago

- Building a 3D Digital Clock with ArduinoPosted 1 year ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 1 year ago

- Snowflake with ArduinoPosted 1 year ago

- Holographic Christmas TreePosted 1 year ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 1 year ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 1 year ago

Ten Open Source Hardware and Design Projects that are setting New Standards

Everything Open Source Hardware

The Open Source hardware and design community is on fire these days. Apart from the projects that eventually already gained worldwide recognition such as Open Source Ecology, DIYDrones, Arduino or RepRap, many fantastic projects, focused on specific aspects, hold great promises.

In the last couple of years, in fact, we have witnessed the emergence of several communities around specific human issues such as construction, transportation, sustainability, fabrication, furniture and even materials.

In this post, we’ll mention ten amazing projects that have potentially revolutionary impacts and already deliver great opportunities to worldwide makers.

A relevant wave of innovations is coming to the architecture and construction market. The most mature project in this knowledge is probably the one initiated by Alastair Parvin, founder of the Wikihouse Project. Wikihouse was presented during 2012, and went through a constant improvement. In the words of the founder:

“Wikihouse project is an Open Source Construction Set, to allow anyone to design, download, and print CNC-milled houses and components, which can be assembled with minimal formal skill or training”

The project, that already shows a great potential, make us glimpse of a lot of potential use cases, ranging from pop-up post crisis hospitality, towards redefining construction for long term sustainability and resilience. As the project is currently rasing funds on it’s website, you’re very encouraged to contribute to the three goals currently set: a Sketchup plugin to allow an easier design process, a Full House prototype or the Platform, an improved community sharing website. (ed: Wikihouse founder Alastair Parvin will be soon interviewed on Open Electronics for your pleasure so, stay tuned).

Wikihouse is not the only open source architectural related project: despite less glossy and design minded, Domeorama (http://www.domerama.com/) is an outstanding community sharing site where tens of Dome designs and junctions are featured in open source.

The website contains an impressive number of resources ranging from calculators to fabrication instructions, materials, software. Impressive stuff.

The design community, didn’t stop after inventing open source structures of houses: in fact, several projects for open source furniture have seen light in the last couple of years. I remember, I was particularly impressed by the beauty and functionality of the AtFab open source furniture designed by Filson and Rohrbacher. See the quality of the collection here on their website: http://www.filson-rohrbacher.com/atfab_12.html.

If not enough, just look at this page now: http://www.filson-rohrbacher.com/ap2-0.html a lot of parametric configurators are available for YOU to design your own furniture, with parametric exploration applets. As some of you may know, in a talk I recently gave at the Barcelona Design Thinking Week, I tried to focus on this precise issue: that of the transformation of the role of the designer, increasingly becoming the one that designs the process that will allow the user herself to become a final product designer.

To our amusement and excitement the innovation pace in the Open Source Design community is so high that we have still a couple of incredible projects to mention. The first one, Open Desk initiative, was recently launched. The project dubs itself to be “about local making” and effectively wants to be a platform to publish open source furniture designs that can be made locally.

All the OpenDesk designs are available as digital downloads. These digital files are fed into a CNC machine, which produces raw sawn pieces of wood. These are finished by hand, a process that can involve oiling, sanding, polishing and small parts. The finished pieces can then be assembled by hand on location.

I wasn’t surprised much to find out that the AtFab collection itself, was recently added to the OpenDesk collection and it’s now available on the platform.

Among other partners the Opendesk initiative was facilitated by FabHub – the global network of fabricators – that now apparently supports Wikihouse as well. Apparently, Fab Hub, OpenDesk, Wikihouse are, at least partially, all expression of the 00:/ strategy & design practice that seems fated to leave a huge footprint in the history of open design and architecture.

These projects, also remind me of the italian Slowd.it or Maker’s Row, projects that are similarly seeking to create a distributed and integrated netowrk of labs, capable of providng the several different material threatments and processing capabilities needed to design complex pieces of furniture or other design products. Even houses.

Another interesting project is that of Sketchair http://www.sketchchair.cc/:

SketchChair is a free, open-source software tool that allows anyone to easily design and build their own digitally fabricated furniture.

In a very similar perspective to that of the AtFab applets, Sketchair is exploring the disappearing limitation between professional, amateur and even improvised designers. Click on the dowload page http://www.sketchchair.cc/download.php choose your operating system and then get crazy designing your own chair and table and sharing the design with the others.

There’s more than open furniture design

Let’s now put the Open source furniture design apart for a while and turn our look to the see or, better, under the sea. Many of you migh probably already know OpenRov the project that waass born to build the first open source submarine rover. The project got some incredible visibility in the last few months, especially when the founder, Eric Stackpole, was featured in a super nice Make cover with a smiling face:

Despite the funny stuff, OpenROV is an amazing project that allows you to build a submarine rover and explore the underwater world for less than one thousand dollars, radically democratizing access to marine research and exploration doing so. We can in fact expect the community to provide new complementary extensions and applications according to the use cases that academics or simple citizen will accomplish with the help of the artifact.

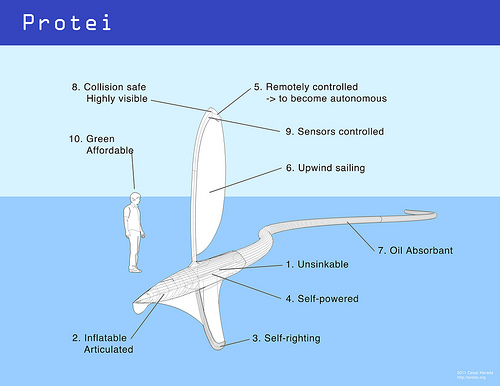

Another impressive project is that founded by Cesar Harada: Protei (http://protei.org/, https://sites.google.com/a/opensailing.net/protei/). According to its website, Protei is:

“Shape Shifting, Open Hardware, Sailing robot to sense and clean the oceans […] a platform technology to transport scientific payload and clean-up equipment at sea, developed by an global community of scientists, engineers, makers and sailors “

A recent post on the TED blog, celebrated the Oceaninc trip (circumnavigating the globe) that Cesar completed thanks to the Unreasonable at the Sea initiative. This initiative actually gave Protei the visibility that the project deserved from the very start. Cesar Harada will be soon interviewed on Open Electronics, so follow us or subscribe to our feed to get informed when the interview will go live.

Leaving the see an shifing our sight to the air for a while, we may notice that the world of UAV (unmanned aerial vehicle) is definitely ramping up in terms of visibility and adoption among hobbyists. While drones are sadly known for warfare related issues, the drone sector is lively and despite one’s mind could easily go towards DIY Drones, the super well know drone firm founded by the former wired director and internet superstar Chris Anderson, another project can count on an even more lively community.

OpenPilot Community can count on a very active forum http://www.openpilot.org/community/ and an impressive list of Airframes to be used with the open source software platofrm. If you just want to be a little more ambitious you can drop the drones and jump on a real open source hardware airplane: indeed that’s the mission of Maker Plane, a project that recently started a campaign to raise money on indiegogo.

The mission of MakerPlane:

“…is to create innovative and game-changing aircraft, avionics and related systems and the transformational manufacturing processes to build them. As a result of this aim, aircraft can be built with consistent, repeatable and highly accurate processes which create safer flying at lower cost. ”

Despite this sounds promising, the project seems a bit too ambitious for now but you know that if the proper community coalize and the power of open source development gets in the picture, we may have an open source, self buildable, airplane sooner than expected.

Despite personal fabrication is a crowded market (as you probably know it also includes our 3Drag, fully open source, super functional and cheap 3D printer based on RepRap, you can buy for an incredible price here http://store.open-electronics.org/3D/Printer/3Drag%203D%20printer%20KIT ) the italian team behind the Fabtotum seems to have struck a relevant chord in makers hearts around. At the time of writing this post, the indiegogo campaign started only few days ago already almost doubled the original objective and tells that the guys here could eventually reach a relevant appreciation from the community.

The Fabtotub dubs itself as being open source:

“Fabtotum is going to be open to improvements and suggestions, with easy access to open source software and schematics“ and declares that the tool will be released under a Creative Commons Attribution – Noncommercial – Share Alike 3.0 Unported License, a not really proper license for those who want to spur an ecosystem.”

In fact, we’re still talking about intent declarations – since the product is still rising funds on indiegogo and will ship in the spring next year – and the lack of clarity on this particular licensing issue, still needs to be clarified once the plan gets more clear. An interview to the Fabtotum team has been published recently on Open Electronics, you can see it here.

Despite we are now quite used to the application of open source paradigms to electronics and fabrication machines – thanks to projects like Arduino and RepRap that actually paved the way for the others to come – this paradigm is increasingly gaining traction and adoption in fields that were usually the reign of closed source development and IPR.

Projects like Robohand, try to break intro the health business, with a powerful vision, that of ultra cutomizable, open and hackable prostetics that every user can tweak and improve by means of few accessible tools suchas a 3D printer, a computer and few other tools that one can easiliy find accessible in any fablab or makerspace scattered around the world. Thinking of particularly complex areas of the world where, due to long lasting conflicts people – and especially childs – are exposed to the threat of landmines we can imagine how projects like robohand will eventually be coupled with the emergence and penetration of a number of fablabs and will represent a real possibility to improve one’s life.

Robohand, got some serious public visibility in July, when Makerbot decided to support the project and help with communicating it to the masses. The project is well documented and you can access the BOM and printing instructions on thingiverse (here http://www.thingiverse.com/thing:64720, http://www.thingiverse.com/thing:44150). By the way, the project still has replicability issues and the community is working on it: you’re welcome to contribute if you think you can help to improve the quality of the solution.

The last project I want to mention here, is still in it’s infancy: La paillasse is an open space for DIY biohacking in Paris, that is interesting by itself as it is opening the doors of Bio Hacking to a growing number of people. The overall excitement with regards to the work done by the group led by Thomas Landrain (president) shall grow even more when you think about an incredible project that is slowly taking off and that, hopefully, will hit public visibility soon: the realization of an open source ink, produced by bacteria. Yes, you’ve heard well: the guys from La Paillasse engineered a process to synthesize a blue ink that could be used in inkjet printers and that is completely biodegradable and environment friendly. From a blog post on Lift conference blog:

“We are finally really excited by the advancement of a project that makes possible to brew yourself a blue ink using bacteria. This first of its kind open-source biological ink is cheap, easy to make, non toxic and easily recycled. When we know that ink is one of the most expensive fluid on the planet and a pollutant, this project could be a milestone for the field and it’s coming from a biohackerspace”

Apparently, the ink project will be soon funded thanks to a crowdunding campaing to stay tuned on La Paillass blog (and on Open Electronics, as we will surely inform you about the progress)

What do you think of these amazing projects? Apparently, the open design and manufacturing paradigms are gaining traction and we still don’t know the many applications that the approach could unleash across a variety of industries. Did we forget any important project that was worth mentioning? Let us know so that we can analyze it more in deep and cover it on open electronics, your source for open innovations and open revolutions.

Did you like the post? Follow @meedabyte and @openelectronics

Pingback: Ten Open Source Hardware and Design Projects th...

Pingback: Ten Open Source Hardware and Design Projects .....

Pingback: Ten Incredible Open Source Design Projects setting New Standard

Pingback: 10 Awesome Open Source Hardware and Design Projects | PDX Currency Corporation

Pingback: Der Open Source Boom – Nordwind